Technology

Project Hy4Smelt

Downloads

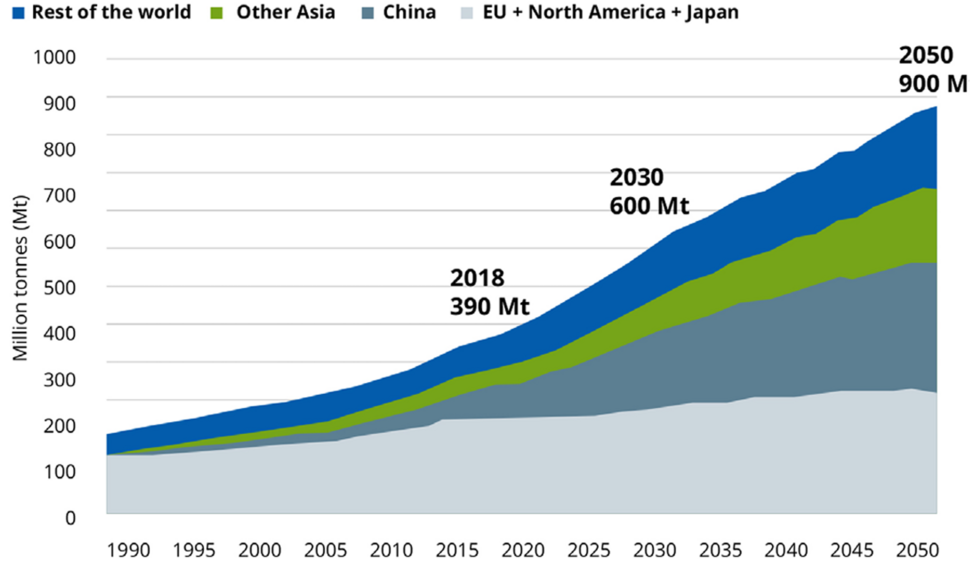

Global Trends for Scrap Availability

Crude steel demand will be 30 % higher in 2050 than it is today. Much of this growth will be in emerging economies with declining demand in China, Europe, Japan, and South Korea. Contribution of scrap in the total steel charge will likely grow to 40 % in 2050 from 30 % than today. Process technologies for OBM (ore based metallics) will have an important role in future CO2 neutral steelmaking.

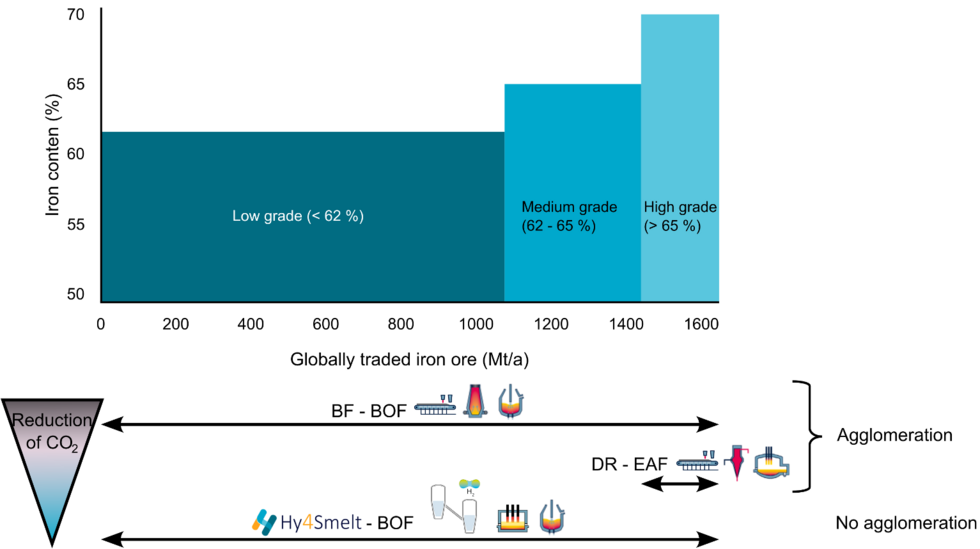

Iron Ore Grades and Process Routes

Majority of iron ores for steel production are fine ores with Fe < 65 %. EAF process is not suitable for melting DRI/HBI with high slag quantities of up to 300 kg/t. Iron ores with Fe > 65 % will not be able to replace low/medium grade ores in the future. Electric smelting furnace (Smelter) in combination with direct reduction enables slag separation for BOF and EAF similar to BF process.

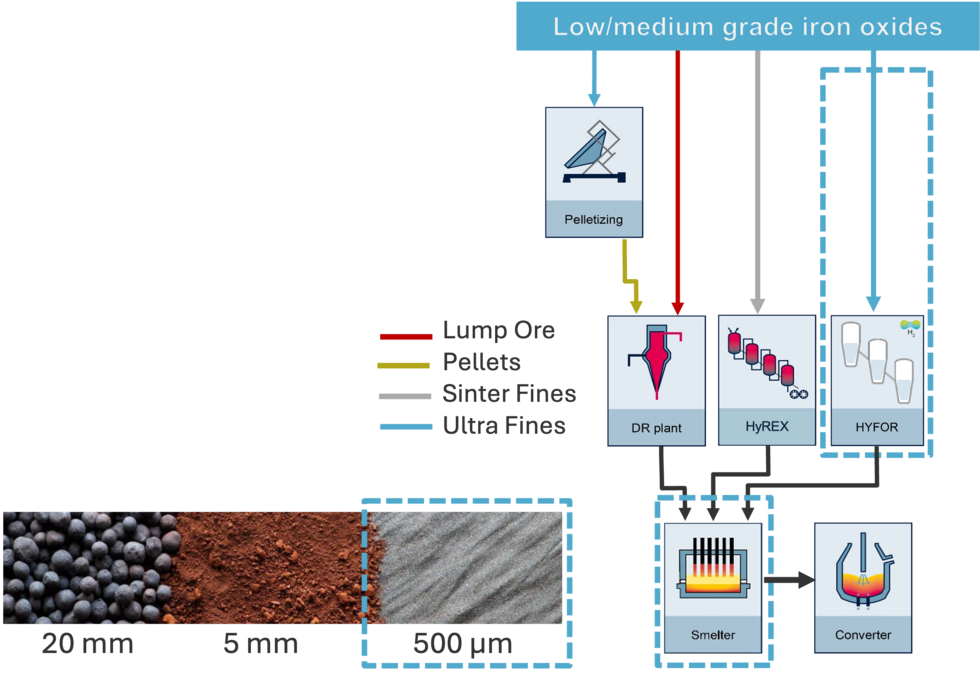

Process Routes for Green Hot Metal

HYFOR (Hydrogen-based fine ore reduction) technology owned by Primetals Technologies Austria is an alternative direct reduction process for ultrafine iron ores that will not require any agglomeration steps. A combination with the Smelter technology (owned by Primetals Technologies Austria) is used for melting and final reduction of direct reduced iron (DRI) based on low and medium grade iron ores with Fe < 65 %. In that way, green hot metal is produced with hydrogen for BOF or EAF steelmaking.

Pilot plant HYFOR

Test the performance of HYFOR reactor and preheating/oxidation cyclone under real operating conditions

Direct reduction of magnetite/hematite iron ore fines with H2 in fluidized bed reactor at 700 °C up to a metallization degree of 97 %

Grain size: < 500 µm

Batch operation with 800 kg ultrafine iron ore is equal to 200 kg DRI per hour

Pilot plant at voestalpine Donawitz site as technical basis for next development phase

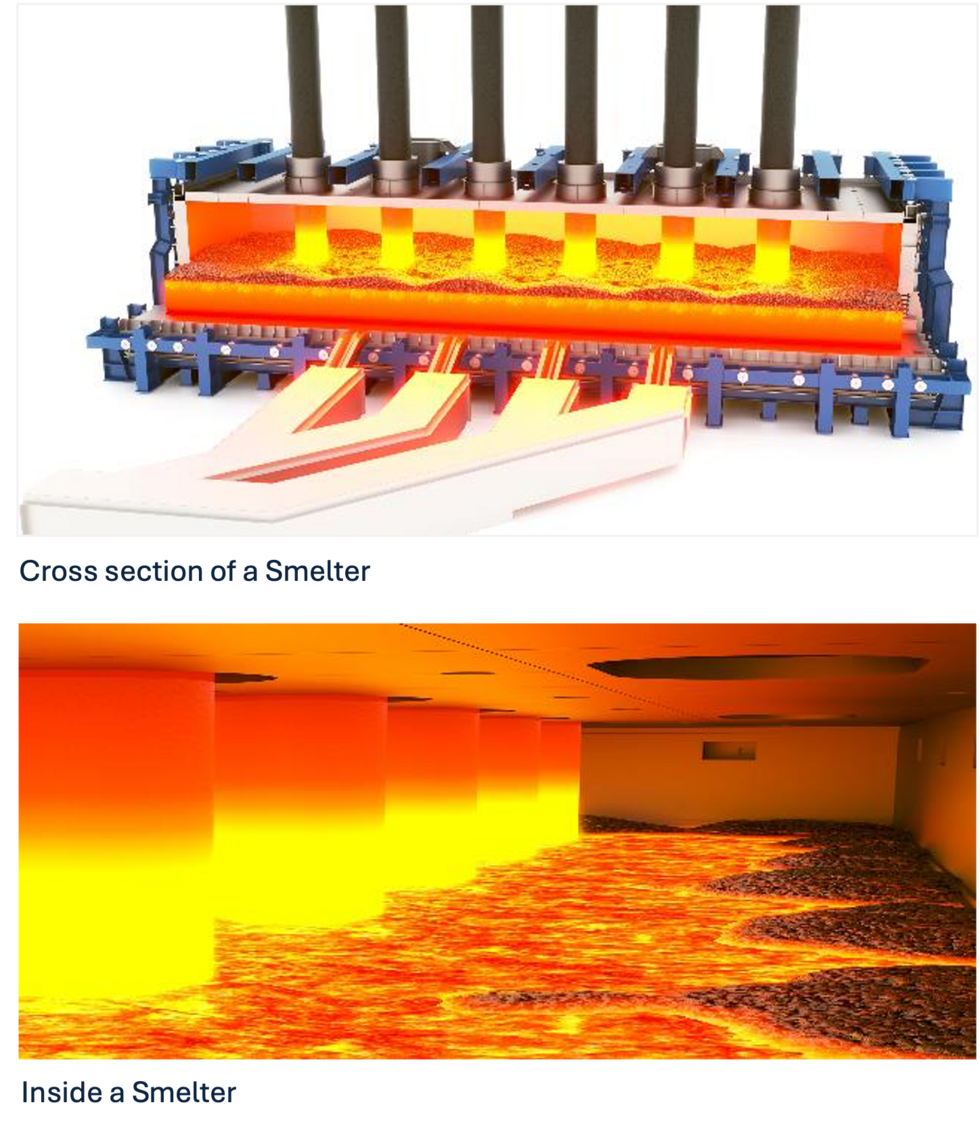

Smelter Process

DRI is molten, final reduction takes place and an adjustment of the iron (carbon level) and slag (basicity, MgO-level).

- Iron from the Smelter go the steel plant

- Slag is granulated and used in cement industry

High calorific off-gas as substitute for natural gas

Due to the reducing atmosphere inside the Smelter, the Smelter is well designed to process other iron oxide containing materials from steel production such as dusts, mill scale or slags to improve the circularity of the production process.

For the Smelter in large scale ironmaking no reference plants exists yet; however, principles were tested and verified by simulations, in the laboratory and on a modified furnace in the hundred kg scale.

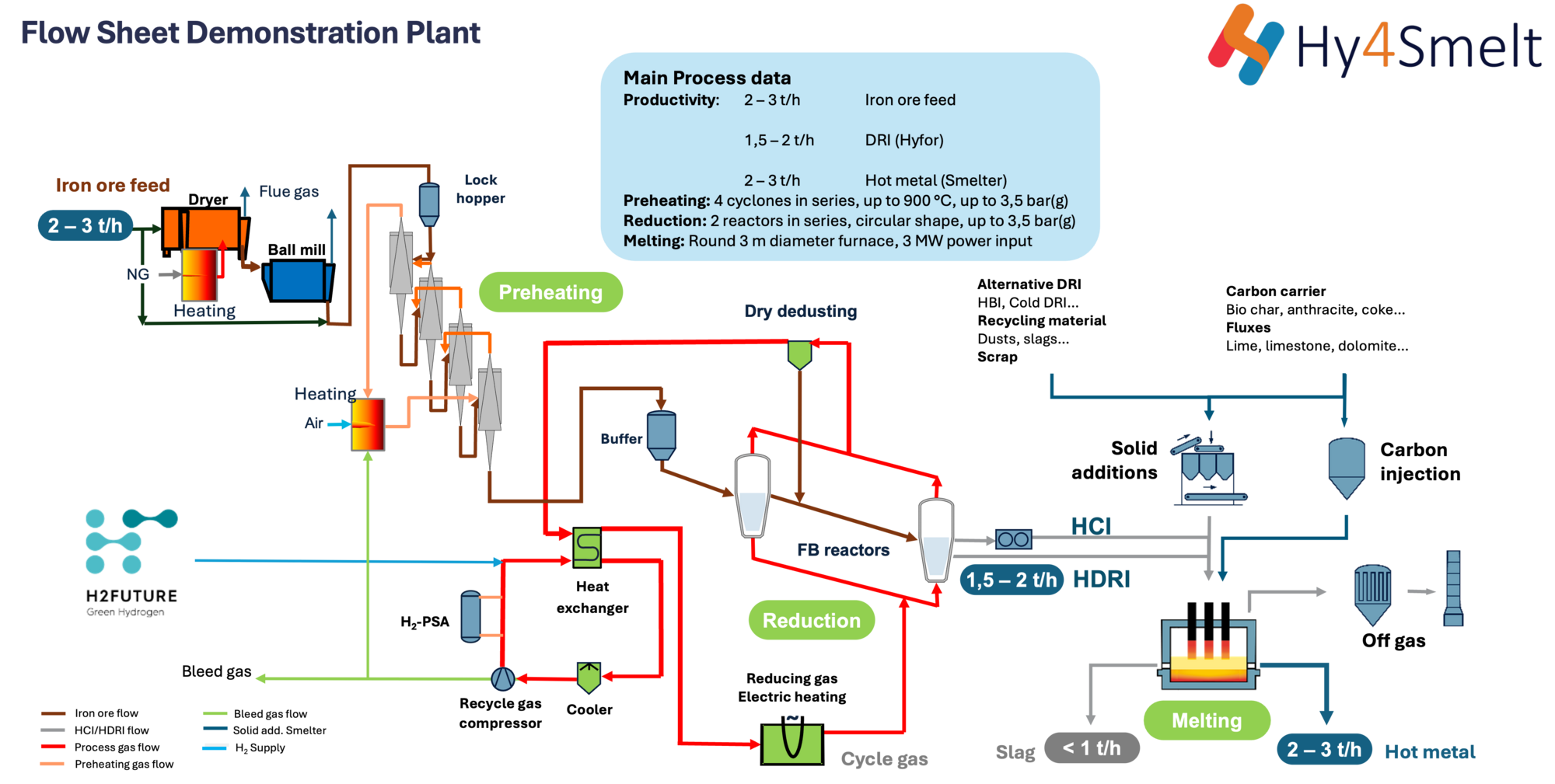

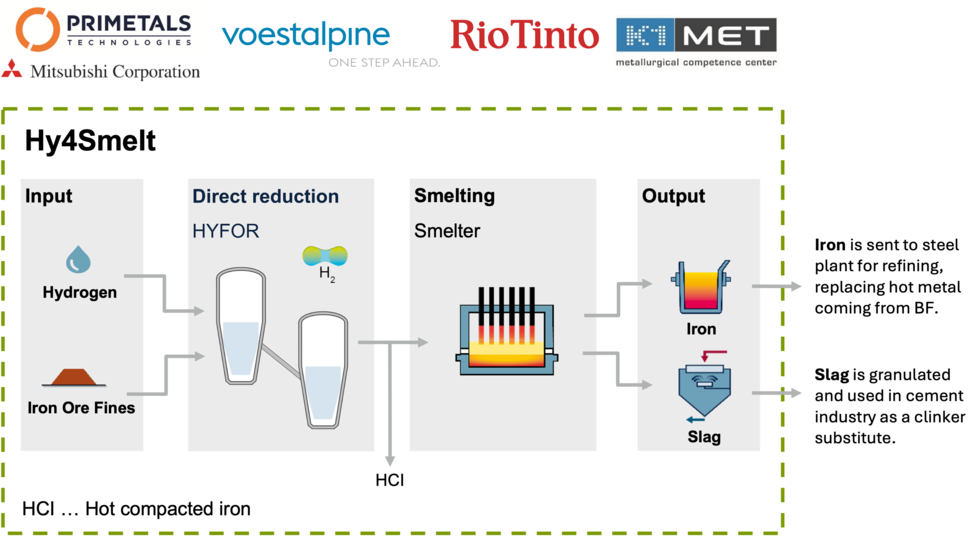

Hy4Smelt is a groundbreaking new process combining direct reduction (HYFOR) and electrified smelting under reducing conditions (Smelter).

In the direct reduction step the iron oxide in the fine iron ore is reduced to metallic iron using only green hydrogen. In the smelting step the direct reduced iron is smelted using green electricity, the melt is adjusted, hot metal (HM) and slag are tapped separately from the furnace.

The Hy4Smelt plant is capable to process a wide range of iron ore fines coming from different mines worldwide. Green energy and bio-carbon in Hy4Smelt allows for carbon neutral iron production.